REVEN® Air-induction Technology

Proven for decades and verified by CFD analysis

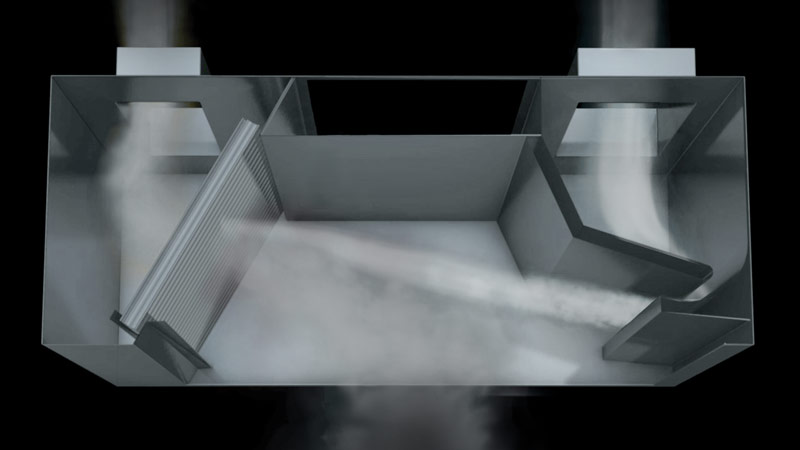

An induction airflow ensures that the entire exhaust air is captured and driven through the separators. In addition, it cools the captured exhaust air and fosters the condensation of vapour molecules at the separator. This increases the efficiency of the separation.

For kitchen ventilation

The benefits of the REVEN® Air-induction System:

- The entire exhaust air is captured, no pollutants escape into the ambient air.

- Thanks to the induction system, draught can be avoided, even if high air volumes are handled.

- The air supplying the induction airflow needs not to be heated. This reduces energy costs.

- The induction airflow is cooler than the exhaust air. Therefore, gas molecules condensate at the separator.

- Our RSC Control adjusts the induction airflow automatically to the cooking intensity.

The small difference

The REVEN® Induction System and the REVEN® EFF System

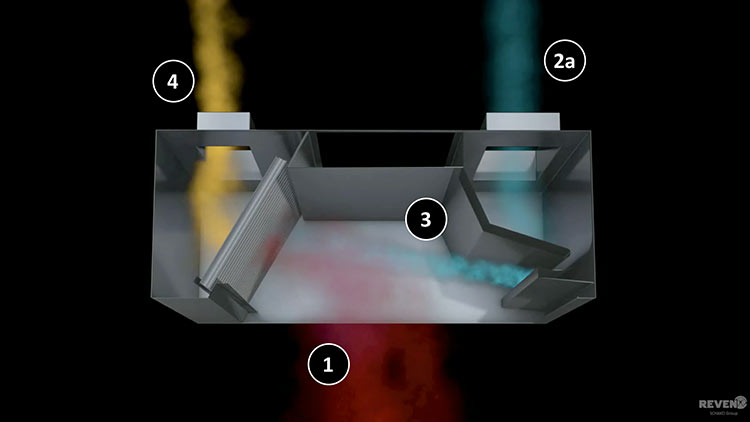

REVEN® Induction System

1 (red):

Cooking fumes, 60 to 80° C

2a (blue):

Filtered untempered fresh air as supply air

3 (blue):

The induction airflow drags cooking fumes to the separator and causes condensation of the air molecules

4 (yellow):

Cleaned exhaust airflow

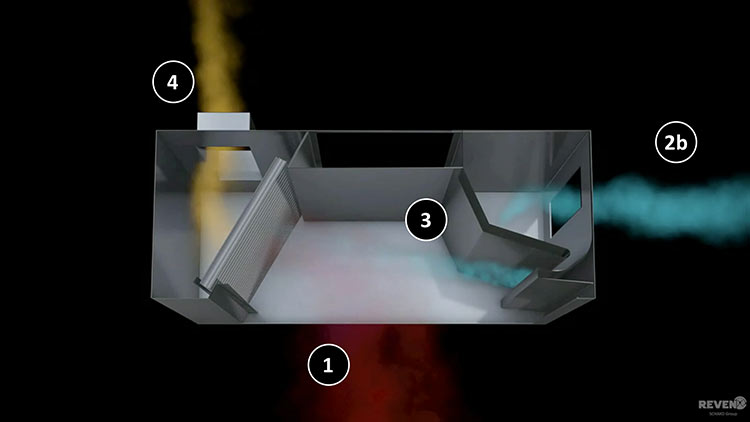

REVEN® EFF System

1 (red):

Cooking fumes, 60 to 80° C

2b (blue):

Sucked-in indoor air at ambient temperature as supply air

3 (blue):

The induction airflow drags cooking fumes to the separator and causes condensation of the air molecules

4 (yellow):

Cleaned exhaust airflow

VIDEO

Watch how the induction systems work in the video.

Our efficient induction hoods comply with the latest state of the art in extraction technology

In a REVEN® Induction System, supply air is blown in (induction) during the fume capture process. This increases efficiency considerably compared to conventional extractor hoods.